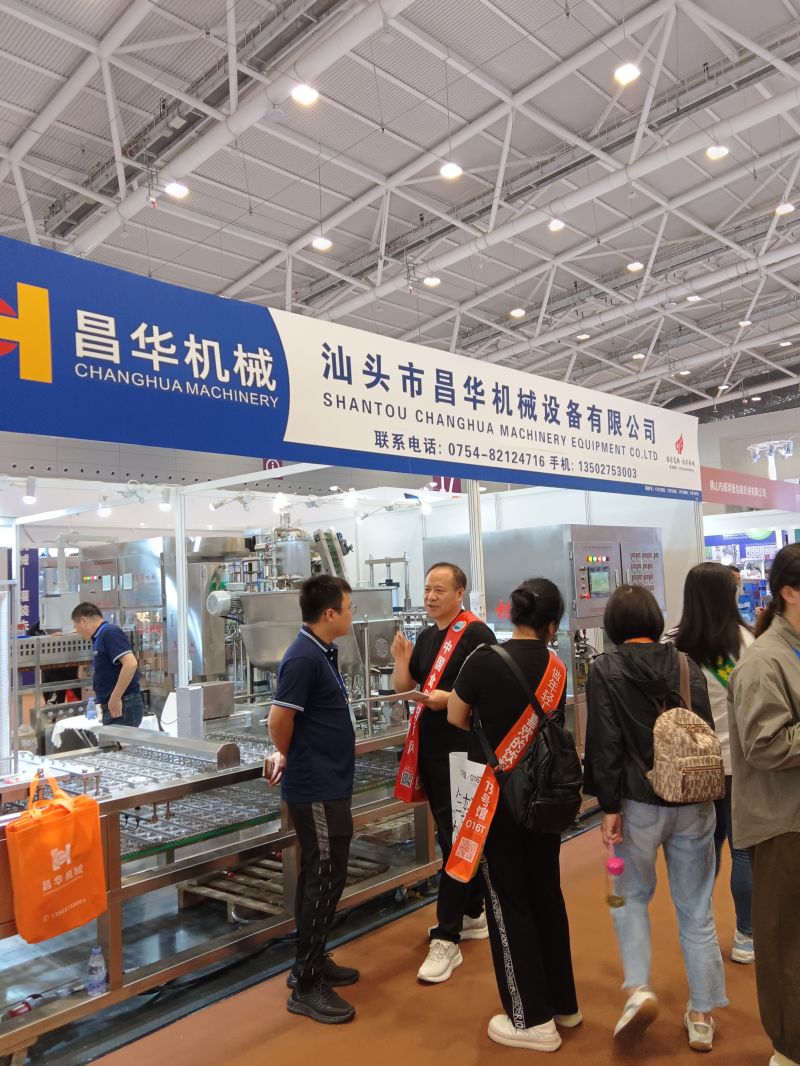

The 8-cup filling and sealing machine is a critical piece of equipment that has revolutionized the beverage packaging industry. Designed for speed and accuracy, this machine has become an essential asset in production facilities around the world.

This cutting-edge machine boasts a user-friendly interface that allows operators to easily control and adjust the filling process. Equipped with advanced sensors, it ensures precise and consistent filling of each cup, eliminating the risk of over orunder filling. This guarantees that every cup provides the perfect portion, meeting the expectations of customers and ensuring their satisfaction.

The 8-cup filling and sealing machine can be customized to accommodate a wide range of cup sizes and shapes, making it a versatile solution for beverage packaging. It incorporates innovative technology that enables it to operate at high speeds, significantly increasing production efficiency without compromising on quality.

One of the key advantages of this machine is its ability to reduce production costs. By automating the filling and sealing process, manufacturers can minimize the need for manual labor. This not only reduces labor expenses but also minimizes the potential for human errors, ensuring consistent and accurate results while minimizing product waste.

Moreover, the 8-cup filling and sealing machine is designed with hygiene in mind. Constructed with materials that are easy to clean and maintain, it prevents accumulation of residue or contamination. This guarantees that each cup is filled and sealed in accordance with the highest standards of cleanliness and food safety.

In conclusion, the 8-cup filling and sealing machine is transforming the beverage packaging industry. Its precision, versatility, and efficiency have revolutionized the filling process, enabling manufacturers to package beverages rapidly and accurately. With its ability to enhance consistency, reduce production costs, and maintain hygiene standards, this machine is an indispensable asset for any beverage production facility.

8-Cup Filling and Sealing Machine: Boosting Efficiency in Beverage Packaging

The 8-cup filling and sealing machine is a critical piece of equipment that has revolutionized the beverage packaging industry. Designed for speed and accuracy, this machine has become an essential asset in production facilities around the world.

This cutting-edge machine boasts a user-friendly interface that allows operators to easily control and adjust the filling process. Equipped with advanced sensors, it ensures precise and consistent filling of each cup, eliminating the risk of over or under filling. This guarantees that every cup provides the perfect portion, meeting the expectations of customers and ensuring their satisfaction.

The 8-cup filling and sealing machine can be customized to accommodate a wide range of cup sizes and shapes, making it a versatile solution for beverage packaging. It incorporates innovative technology that enables it to operate at high speeds, significantly increasing production efficiency without compromising on quality.

One of the key advantages of this machine is its ability to reduce production costs. By automating the filling and sealing process, manufacturers can minimize the need for manual labor. This not only reduces labor expenses but also minimizes the potential for human errors, ensuring consistent and accurate results while minimizing product waste.

Moreover, the 8-cup filling and sealing machine is designed with hygiene in mind. Constructed with materials that are easy to clean and maintain, it prevents accumulation of residue or contamination. This guarantees that each cup is filled and sealed in accordance with the highest standards of cleanliness and food safety.

In conclusion, the 8-cup filling and sealing machine is transforming the beverage packaging industry. Its precision, versatility, and efficiency have revolutionized the filling process, enabling manufacturers to package beverages rapidly and accurately. With its ability to enhance consistency, reduce production costs, and maintain hygiene standards, this machine is an indispensable asset for any beverage production facility.

Post time: Oct-24-2023